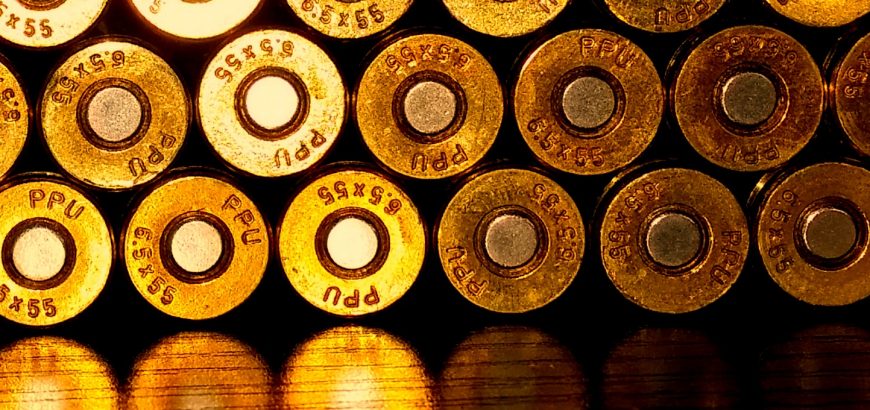

Reloading not only allows us to create accurate rounds tailored to specific rifles, but also helps to keep down the cost of shooting. Components can be costly in New Zealand, especially powder which accrues charges for dangerous-goods handling.

The cost of reloading of in New Zealand can be high compared to buying components in the States, and unfortunately a lot of this does come down to those handling charges. Whether it’s the shipping, handling and import charges on bullets and brass or the explosives handling fees on powders and primers, there’s always something that makes it more costly to assemble your own ammunition at this end of the world.

Fortunately there are a couple ways to reduce the cost of hand loading your own ammo. Here are two that I recommend.

1. Shopping around

There are numerous gun stores in Auckland and the rest of New Zealand that sell reloading components. There may only be a few major ones, but there are also plenty of local shops that stock what you need.

In order to find the most cost-effective way to produce match-accuracy rounds I put together a spread sheet comparing the cost of the primers, brass, powder and projectiles at around eight different stores. By comparing prices around the country I managed to shave off more than 50 cents a round. That’s $50 per hundred rounds. Not bad.

When shopping around, don’t forget to account for courier fees. For example, when purchasing some Sierra projectiles I found that the cheapest store in the country was around $10 cheaper than my nearest gun store. Given the $4.50 courier charge and the time it would have taken to reach me, I opted to go the slightly more expensive route.

2. Economise where possible…

…without sacrificing quality. In some areas you may wish to spend a tiny bit more. For example, Federal Large Rifle Match primers cost me less than a dollar more per 100 than less consistent primers. That’s an area where I don’t mind spending a tiny bit more.

When it comes to economising, not everyone can afford to buy vast quantities of powder at a time. However, you can increase your powder economy by 10 per cent very easily.

ADI Powders are manufactured in Australia, and as a lot of shooters know, many Hodgon powders are produced at the ADI plant. In fact, ADI provides a handy sheet that lets you find the Hodgon equivalents of their powders. There is also info for other manufacturers as well.

The reason this is such a bonus for New Zealand reloaders is that not only can you support a company that is kind of local (across the ditch is better than across the world), but if you buy their 500 gram containers, you’ll be getting 10 per cent more than an American manufactured equivalent 1lb which is 454 grams. Usually at the same price too.

There are always ways to make your reloading cheaper, hope these two help!