Everybody has their personal references when it comes to cleaning their rifles. From the guys who wipe down with an oily rag to those that give their gun a thorough birthday every time it sees fresh air, everyone got the “perfect” cleaning method.

I’ll be honest. The way I clean my guns may not suit you, or it could be just what you like. So why bother going through the whole process? There are plenty of books, product manuals and nooks of the internet that will give you all the info you need to clean a weapon. And they’ll likely all be different. If you’re starting out in shooting, read a few of these, hop on the online forums and figure out your own path.

So, instead of running you through cleaning from start to finish (which you have your own ideas on), I’ll go over a few quick tips which you may not have encountered.

3 quick tips for cleaning your rifle faster

1. Roll-your-own

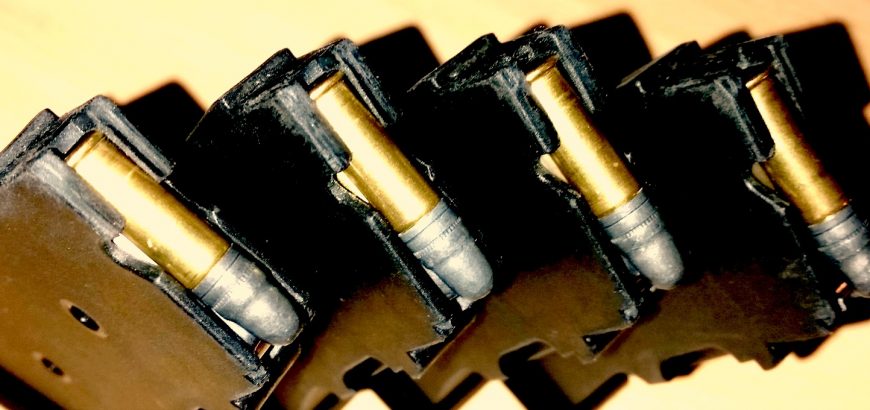

It’s annoying isn’t it? You run a patch through your bore and it comes out filthy, but only a tiny bit of it. So you end up going through a bunchy of patches (and time) trying to get as much gunk out of your rifle as possible.

Well, instead of threading your patch through, you can either use circular patches to make a swab (not my favourite – too much effort), or roll your patch around a Parker Hale style jag. Instead of having only the front tip of your cloth/jag picking up dirt, you create a cylinder that exposes the sides of the jag to the barrel. This way you use almost the entire patch, instead of about a quarter of it.

Here’s a great blog post on brush/jag types and different solvents. If you’re starting out and figuring your way around cleaning a rifle, it’s a good place to start from.

2. Go both ways

A lot of people will tell you to never run a brush both ways through the barrel. Why? Because they don’t want to damage the crisp edge of the crown – the very last surface contact a projectile has with your rifle’s barrel. While there is some merit to this thinking, the effects of a brass/bronze brush, or even a nylon brush, on hammer forged steel should be minimal.

I’m not as gung-ho about this as some people who will vigorously scrub with the brush completely exiting the bore, but I will happily pull my brush backwards and forwards through the barrel, without pushing the entire brush through. It just makes me feel better. I give the whole barrel a thorough going over and push the brush out at the end and remove the brush before pulling the rod back through.

And no, never clean from the muzzle end. There are too many reasons why you shouldn’t and none why you should. Aside from protecting the crown, you don’t want to push all the junk back into your action and magazine.

However, your solvent should be doing most of the work when it comes to cleaning, so you should only really be brushing if you are dealing with a heavily fouled barrel.

3. Leave it wet

Yup, that solvent should do most of the job. So why not leave it working? Once you’ve got your barrel to an acceptable level, I like to run another wet patch through.

For a rifle I shoot fairly regularly, I will run a patch of Hoppe No. 9 through and let the solvent work away. Before shooting I’ll put a dry patch through and be surprised (every time) at how much carbon and copper had been too stuck in there to come out the first time.

If I’m cleaning a rifle that will likely go back in the safe for a few months, the last patch I’ll run through will be soaked in lubricating oil. Not because I’m trying to lube anything up, but because it has a high viscosity and likes to cling to the inside of the barrel, instead of running out like regular oil. This will be a protective layer that will inhibit any rust formation. A rifle that is being stored in the safe for that long usually gets a wipe down all over the metal and wood with an oily rag, to keep everything from getting that thin layer of red that likes to pop up in safes in Auckland’s muggy climate.

Hope that’s clear as mud! Leave your own cleaning tips in the comments below.